| Weight | 0.19 lbs |

|---|

BI34 F 24VDC 25%ED

Price Summary

- $80.60

- $80.60

- $80.60

Be the first to review “BI34 F 24VDC 25%ED” Cancel reply

You must be logged in to post a review.

Related Products

Recently Viewed

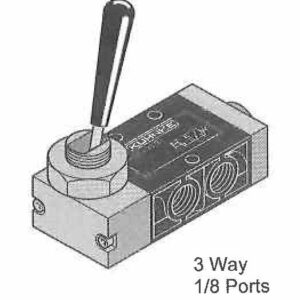

Item # 75042-25-00

Lever valves can be used to manually switch air supplies on equipment or operate cylinders and other devices. Valves can be panel mounted or fastened to a surface via body mounting holes. Handles have a contemporary black molded grip and require 3.4 lbs. of force to operate. Valves are available in spring return, pneumatic return and maintained position versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

For normally open function on 3 way valves, reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4 ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of 4 way 1/8 ported valves are 3.75″ L x 1.375″ W x 0.75″ D. For 1/4 ported valves: 4.75″ L x 2″ W x 1″ D. For 3 way valves subtract 0.75″ from L dimension. For pneumatic return valves add 1″ to L dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

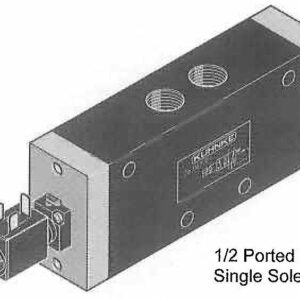

Item # 76327-91-00

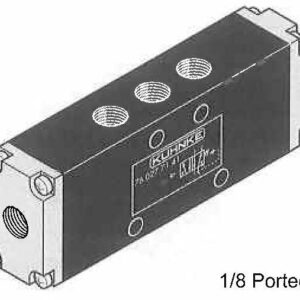

Solenoid operated, air piloted poppet valves are available in single, double, priority and external air pilot supply versions. Priority version overrides signal from opposite solenoid to assure return to valve home position. Valves with external air pilot connections are used when switching pressures below 35 PSI.

Poppet valves usually provide higher flow rates than other types of valves because of flow path design.

Valves include a red manual override for easy testing. Encapsulated coils provide splash proof protection when used with plug connectors. Valves can be mounted individually using through body holes or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures).

Through body holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4 ? for 1/2 ported valves.

For valve specifications see appendix. See accessory section for connectors and manifolds. For detail dimensions contact factory.

Item # 75023-27-41

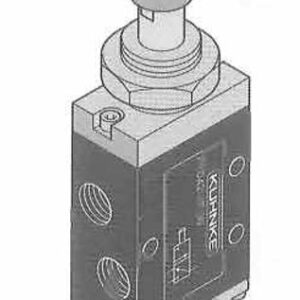

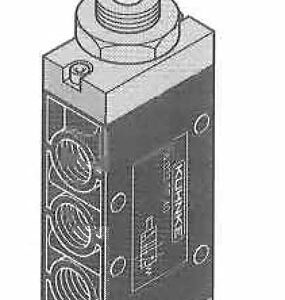

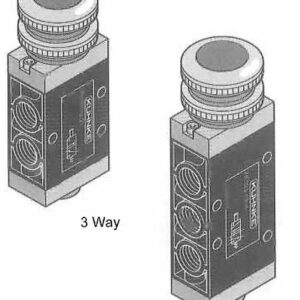

Knob valves have a small travel of about 1/4 inch and can be easily operated with the palm of a hand. Knobs are constructed of sturdy black molded material. Available in spring return, pneumatic return and push-pull versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI: 1/8 port approx. 3.4 Lbs., 1/4 port 11.3 Lbs.

For normally open function on 3 way valves reverse connect ports 1-3. For 2 way operation, plug port 3. Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Above panel dimensions: 1/8-ported are 1″ Dia. x 1.5? H: 1/4-ported -1.5″ Dia. x 2.25″ H.

Typical behind panel dimensions of 4 way 1/8 ported valves are 2.5″ D x 1.375″ W x 0.75″ H; 1/4 ported valves- 4″ D x 2″ W x 1″ H. For 3 way valves subtract 0.75″ from depth. For pneumatic return add 1″ to depth dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 76440-01-07

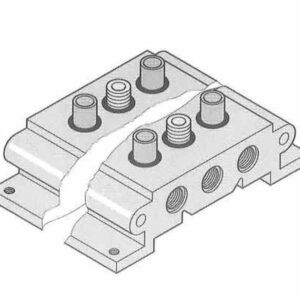

Two sizes of common input manifolds are available. Manifolds are aluminum bars, predrilled and tapped; with common 1/4 metric supply ports on each end. For NPT supply ports, order supply line adaptor kit separately. Manifold kits include valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the bar and supply the line air pressure. Optional mounting bracket kits for supporting the manifold are available in 2 heights to accommodate the size of valves used.

Item # 76123-71-41

Spool valves rely on a stainless steel spool moving within a sleeve to direct flow to the ports of the valve. Spool designs are known for their long life capability. Available in single, double or with priority port actuators. The priority port design overrides the signal from the opposite pilot operator to insure return to home position. Pneumatically actuated spool valves are available in 1/8 and 1/4 port sizes and require a minimum of 35 PSI operating pressure. Valves can be mounted individually using through body holes or assembled on manifolds.

Pilot port size (for actuation): 1/8 for all size valves.

Operating pressure range 35 to 145 PSI. Actuation force (pilot pressure): 35 PSI minimum.

Mounting via 4 through body holes 3/16″ Dia.

For valve specifications see appendix. See accessory section for manifolds if required. For detail dimensions contact factory.

Item # 75266-11-00

Valves are similar to the standard 3 way valves shown on the opposite page except have been modified with special seals and springs for vacuum applications. Valves have an external air supply port required to operate the pilot valve.

Through body holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4 ” for 1/2 ported valves.

For valve specifications see appendix. See accessory section for electrical connectors. For detail dimensions contact factory.

Item # 75024-71-38

Spool valves rely on a stainless steel spool moving within a sleeve to direct flow to the ports of the valve. Spool designs are known for their long life capability. Available in single, double or with priority port actuators. The priority port design overrides the signal from the opposite pilot operator to insure return to home position. Pneumatically actuated spool valves are available in 1/8 and 1/4 port sizes and require a minimum of 35 PSI operating pressure. Valves can be mounted individually using through body holes or assembled on manifolds.

Pilot port size (for actuation): 1/8 for all size valves.

Operating pressure range 35 to 145 PSI. Actuation force (pilot pressure): 35 PSI minimum.

Mounting via 4 through body holes 3/16″ Dia.

For valve specifications see appendix. See accessory section for manifolds if required. For detail dimensions contact factory.

Item # 76420-02-06

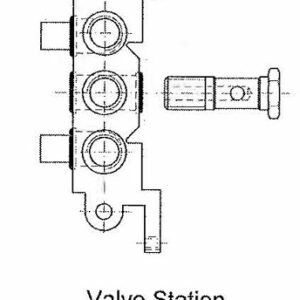

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 75022-62-23

Flush Head pushbuttons are used to prevent accidental operation or provide flat panel appearance. Button is flush with shroud surface and diameter is 1-3/8 inch.

Operating pressure range is 0 to 145 PSI. Actuation force at 90 PSI. is approx. 7.9 Lbs.

For normally open function on 3 way valve reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole is 1 3/16 inch (30 mm) diameter. Above panel dimensions are 1.375″ Dia. x 0.875″ H. (Mushroom) or 0.375″ H. (Flush Head).

Behind panel dimensions of 3 way valve – 3.25″ D x 1.375″ H x 0.75″ W; 4 way valve- 4″ D x 1.375″ H x 75″ W. Allow space for fittings and tubing.

Valve through body mounting holes are 3/16″ diameter.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75023-23-42

Used as a pneumatic limit switch or position detector. Roller arm travel is 3/8? (10mm). Actuating force is 4.5 Lbs. Options include valves with pneumatic reset used in conjunction with other controlling devices to reset valve. A double roller lever valve can be used on machine carriages to reverse direction of travel.

Operating pressure range is 0-145 PSI. Actuation force @ 90 PSI, is approx. 4.5 Lbs.

For normally open function on 3 way valve, reverse connect ports 1-3. For 2 way operation, plug port 3.

Typical valve body dimensions are 2.5? L (3 way), 3.15? L (4 way) x 1.375? H x .75? W. Add 1? to L dim. for pneumatic reset types. Through body mounting holes are 3/16? diameter.

Roller Lever extends 1.343? beyond body and travel is .39? +/- .04?.

For valve specifications see appendix. For detail dimensions contact factory.

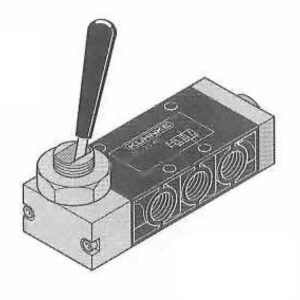

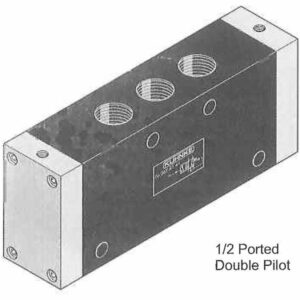

Item # 76127-71-42

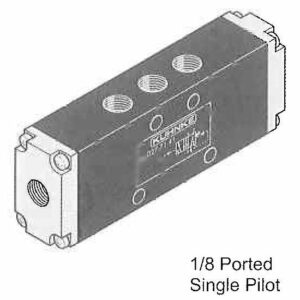

Pneumatically operated poppet valves are available in single, double or with priority port actuators. The priority port design overrides the signal from the opposite pilot operator to insure return to home position. Poppet valves rely on O rings and gaskets to seal passage ways within the valve and generally offer higher flow rates than other types of valves.

These valves are available in port sizes of 1/8, 1/4 and 1/2. Pilot ports are 1/8 for all size valves and require minimum of 35 PSI operating pressure. Single air pilot valves have an air supported spring return and require a pilot pressure equal to or greater than the air supply pressure at port 1. Valves can be mounted using through body holes or assembled on manifolds.

Pilot port size (for actuation): 1/8 for all size valves.

Operating pressure range 35 to 145 PSI. Actuation force (pilot pressure): 35 PSI minimum.

Mounting via 4 through body holes 3/16? Dia. (1/2? ported valves- 1/4? Dia.).

For valve specifications see appendix. See accessory section for manifolds if required. For detail dimensions contact factory.

Item # 76420-02-10

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 76411-00-01

For use on ISO valves with CNOMO air pilots.

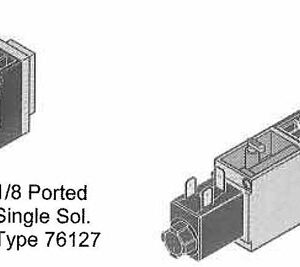

Item # 76067-91-00

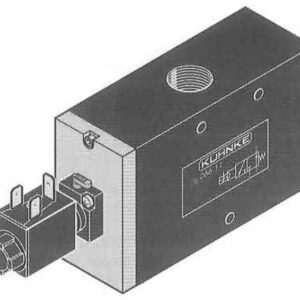

Solenoid operated, air piloted poppet valves are available in single, double, priority and external air pilot supply versions. Priority version overrides signal from opposite solenoid to assure return to valve home position. Valves with external air pilot connections are used when switching pressures below 35 PSI.

Poppet valves usually provide higher flow rates than other types of valves because of flow path design.

Valves include a red manual override for easy testing. Encapsulated coils provide splash proof protection when used with plug connectors. Valves can be mounted individually using through body holes or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures).

Through body holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4 ? for 1/2 ported valves.

For valve specifications see appendix. See accessory section for connectors and manifolds. For detail dimensions contact factory.

There are no reviews yet.