Shopping cart is empty!

Item # PT45KY1

Highlights:

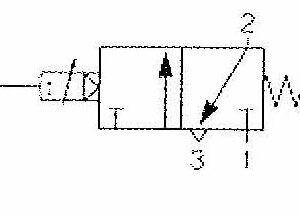

The PT timer is an adjustable precise time delay pneumatic device. The timer is available with an on delay (NC), or an off delay (NO) output. The timer has 1/8 inch NPT ports.

The PT series timer combines a pneumatic timing mechanism with a floating spool valve assembly to provide a wide range of adjustable time control for fluid power systems. The timing assembly, which operates independently of the control pressure, is available in nine different ranges from one tenth of a second to 60 minutes, adjustable by means of a time-calibrated dial. Timing action is initiated by a motor diaphragm operated by a control pressure of from 5 to 140 PSIG.

The timer is equipped with a multi purpose 3 way output valve allowing it to be used as normally open, normally closed or as a diverter.

The PT is designed for panel or surface mounting. Panel mounted versions include a 3 13/16 inch square bezel while surface mounted units are equipped with a bracket for vertical mounting. If required, The PT can be specially calibrated for mounting horizontally.

Off Delay Timer Operation Applying pilot pressure of at least 100ms in duration to the control port shifts the valve. When the pilot pressure is removed, the timing sequence begins. After the timer reaches its set time, the valve switches off. Re-applying the pilot pressure resets the timer and valve.

Item # SPA1A

Highlights:

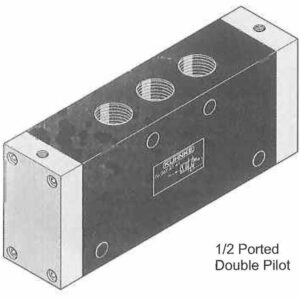

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item # SPA1B

Highlights:

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item # SPA1C

Highlights:

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item # SPA2A

Highlights:

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item # SPA2B

Highlights:

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item # SPA2C

Highlights:

The PMT, whether panel or base mounted, requires a subplate for connecting fittings and air lines. Several types are available to suit connection needs. The subplate is supplied loose and unmounted, as a separate item.

Item #76047-81-42

Highlights:

Pneumatically operated poppet valves are available in single, double or with priority port actuators. The priority port design overrides the signal from the opposite pilot operator to insure return to home position. Poppet valves rely on O rings and gaskets to seal passage ways within the valve and generally offer higher flow rates than other types of valves.

These valves are available in port sizes of 1/8, 1/4 and 1/2. Pilot ports are 1/8 for all size valves and require minimum of 35 PSI operating pressure. Single air pilot valves have an air supported spring return and require a pilot pressure equal to or greater than the air supply pressure at port 1. Valves can be mounted using through body holes or assembled on manifolds.

Pilot port size (for actuation): 1/8 for all size valves.

Operating pressure range 35 to 145 PSI. Actuation force (pilot pressure): 35 PSI minimum.

Mounting via 4 through body holes 3/16? Dia. (1/2? ported valves- 1/4? Dia.).

For valve specifications see appendix. See accessory section for manifolds if required. For detail dimensions contact factory.

Itme # 50706

Highlights:

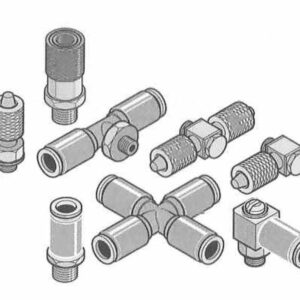

Brass metric sized fittings provide a full family of connectors for most applications in miniature pneumatics. Machined from solid brass stock, fittings are dependable, easy to install and reduce space requirements.

Series 50 fittings also include quick connect couplings and brass manifolds.

Max. Tightening torque 1.5 lbs. Self sealing thread. Temperature range -10? C to + 40? C.

Itme # 50880-00-20-00

Highlights:

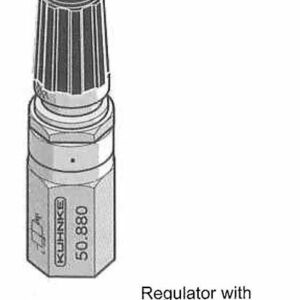

The sub-miniature Series 50 regulator provides regulation of air pressure from 0 to 115 PSI. Available in both relieving and non-relieving versions, the unit’s size and shape makes it ideally suited for mounting in dental, medical and laboratory equipment where close regulation and fine adjustments are necessary.

The regulator is supplied with a panel nut for mounting in a 1/2 inch diameter hole. It can be screw driver adjusted, and set with a locking nut, or with the use of a control knob can be continuously adjusted. Ports (2) have 10-32 (M5) threads and are 180? apart on the side of the regulator body. The housing is nickel plated brass.

Several adjustment ranges are available for close regulation in most applications. Special designs are available.

Itme # 51018-00

Highlights:

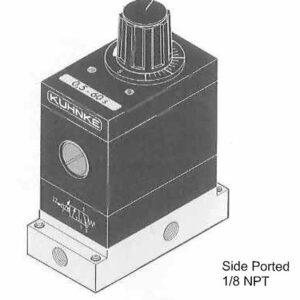

The Series 51 timer is an adjustable precise time delay control device. The timer is available with either an on delay- (NC) or off delay- (NO) 3 way built-in valve. It is designed for mounting along with valves or other logic devices and is available with 10-32 (M5) bottom ports, or 1/8″ NPT side ports. Bottom ported timers can also be panel mounted using (2) threaded M3 inserts on the top cover.

Timing operation can be set up in 2 ways; either via direct connection of the pressure line to be timed (1/8″ NPT ported only) or via a separate pilot signal. When pressure is applied to the input (or pilot port) the timing sequence begins by setting a vacuum within the timer. Using atmospheric pressure (independent of line pressure), the timer begins the preset timing cycle. At the end of the cycle an internal 3 way valve is switched providing an output. The timer resets automatically after removal of the control signal.

Itme # 51018-01

Highlights:

The Series 51 timer is an adjustable precise time delay control device. The timer is available with either an on delay- (NC) or off delay- (NO) 3 way built-in valve. It is designed for mounting along with valves or other logic devices and is available with 10-32 (M5) bottom ports, or 1/8″ NPT side ports. Bottom ported timers can also be panel mounted using (2) threaded M3 inserts on the top cover.

Timing operation can be set up in 2 ways; either via direct connection of the pressure line to be timed (1/8″ NPT ported only) or via a separate pilot signal. When pressure is applied to the input (or pilot port) the timing sequence begins by setting a vacuum within the timer. Using atmospheric pressure (independent of line pressure), the timer begins the preset timing cycle. At the end of the cycle an internal 3 way valve is switched providing an output. The timer resets automatically after removal of the control signal.