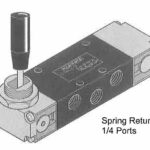

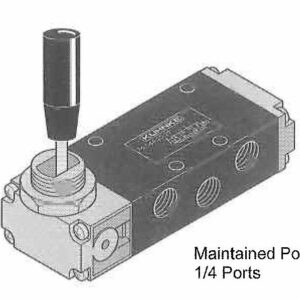

| Description | Spring Return to Center All ports open in center position. |

| Port Type | 1/4 Metric Ports (European Std.) |

| Orifice | 0.315 in. 6 mm |

| Body No. | 4S |

| Length | 5.375 in. |

| Width | 2 in. |

| Depth | 1 in. |

| Panel Mounting Hole | 7/8 in. |

| Body Mounting Hole | 3/16 in. |

| Operating Pressure Range | 0 to 145 psi |

| Actuation Force @ 90 PSI | Approx. 3.4 lbs. |

| Cv | 0.87 |

| Kv | 12.4 |

| Flow @ 45 PSI | 22.4 SCFM |

| Flow @ 90 PSI | 39.2 SCFM |

| Flow @ 145 PSI | 63.5 SCFM |

| Flow @ 3 Bar | 635 lpm |

| Flow @ 6 Bar | 1110 lpm |

| Flow @ 10 Bar | 1800 lpm |

Intended Use-?Series 75 and 76 valves are intended for general purpose industrial applications utilizing normal shop air supply systems. For special applications with other media or other environments, contact Kuhnke.

Media-?Compressed air or other neutral gases, properly filtered. For applications on liquids contact Kuhnke.

Lubrication-?Valves operate on lubricated or non-lubricated systems. After using components in a lubricated system, do not switch to an un lubricated system. Avoid over lubrication.

Vacuum Applications-?Spool Valve designs can be applied on vacuum systems. For applications using poppet valves, use only specially assembled valves shown in the catalog.

Dimensions and Design Changes-?All dimensions in this catalog are approximate, if necessary, detailed drawings can be obtained from Kuhnke or from one of the Kuhnke websites. Dimensions, valve design and materials are subject to change without notice.

Metric and NPT threads-?Although similar in size, valve port threads in metric ported valves are different from NPT versions. NPT versions have a tapered thread that is used to form a seal with the fitting thread. Metric thread is straight, and the seal is provided by an o-ring or washer normally included with the connection fitting. Metric fittings can be used on NPT threaded valves, but NPT fittings cannot be used on metric threaded valves.

There are no reviews yet.