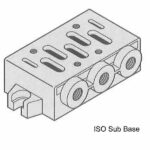

| Description | Sub base ISO 1 |

Item # 76420-00-11

Price Summary

- $33.94

- $33.94

- $33.94

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

| Weight | 0.19 lbs |

|---|

Be the first to review “Item # 76420-00-11” Cancel reply

You must be logged in to post a review.

Related Products

Item # 76420-00-13

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Item # 76420-00-14

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Item # 76420-00-12

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Recently Viewed

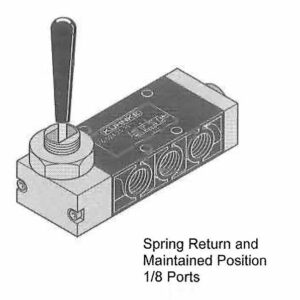

Item # 75024-25-38

Three position valves are used mostly to position cylinders manually. The operator controls the cylinder direction by moving the lever side to side. Valves with all ports open in the center position allow the cylinder piston rod to move freely, while valves with all ports closed in the center position will hold the cylinder in the desired position when the lever is returned lo center. Valves can be panel or body mounted.

Operating pressure range Is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of spring return 1/8 ported valves are 4″ L x 1.375″ W x .75″ D. For 1/4 ported valves: 5.375″ L x 2″ W x 1″ D. Above panel dimensions including handle for 1/8-ported valves – 2.5″. 1/4-ported valves -3.375″. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

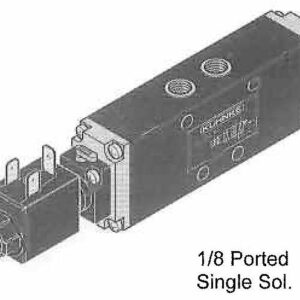

Item # 75023-91-00

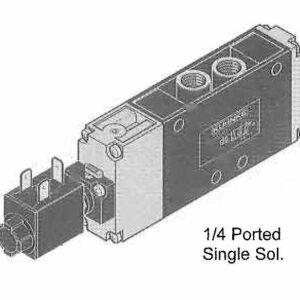

Solenoid operated, air piloted spool valves are available in single, double, priority and external air pilot versions. Valve designs use a stainless steel spool moving within a sleeve to direct airflow to the ports of the valve. Spool valves are known for their long life capability.

Valves are available in 1/8 and 1/4 port sizes and have an operating range of 35 to 145 PSI.

Valves include a red manual override and encapsulated coils and can be individually mounted or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures.)

Through body mounting holes are 3/16″.

For valve specifications see appendix. See accessory section for electrical connectors and manifolds. For detail dimensions contact factory.

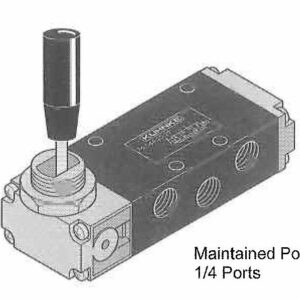

Item # 75023-27-42

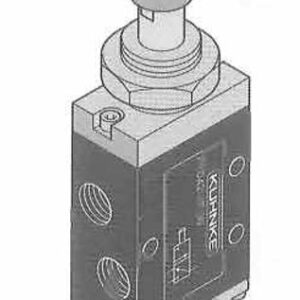

Knob valves have a small travel of about 1/4 inch and can be easily operated with the palm of a hand. Knobs are constructed of sturdy black molded material. Available in spring return, pneumatic return and push-pull versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI: 1/8 port approx. 3.4 Lbs., 1/4 port 11.3 Lbs.

For normally open function on 3 way valves reverse connect ports 1-3. For 2 way operation, plug port 3. Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Above panel dimensions: 1/8-ported are 1″ Dia. x 1.5? H: 1/4-ported -1.5″ Dia. x 2.25″ H.

Typical behind panel dimensions of 4 way 1/8 ported valves are 2.5″ D x 1.375″ W x 0.75″ H; 1/4 ported valves- 4″ D x 2″ W x 1″ H. For 3 way valves subtract 0.75″ from depth. For pneumatic return add 1″ to depth dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75044-02-00

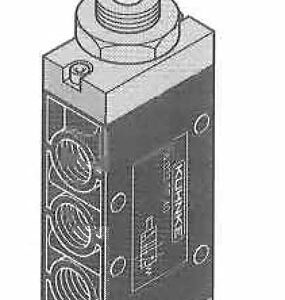

Solenoid operated, air piloted poppet valves are available in single, double, priority and external air pilot supply versions. Priority version overrides signal from opposite solenoid to assure return to valve home position. Valves with external air pilot connections are used when switching pressures below 35 PSI. Poppet valves usually provide higher flow rates than other types of valves because of flow path design. Valves include a red manual override for easy testing. Encapsulated coils provide splash proof protection when used with plug connectors. Valves can be mounted individually using through body holes or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures).

Through body mounting holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4″ for 1/2 ported valves.

For valve specifications see appendix. See accessory section for electrical connectors. For detail dimensions contact factory.

Item # 75024-25-38

Three position valves are used mostly to position cylinders manually. The operator controls the cylinder direction by moving the lever side to side. Valves with all ports open in the center position allow the cylinder piston rod to move freely, while valves with all ports closed in the center position will hold the cylinder in the desired position when the lever is returned lo center. Valves can be panel or body mounted.

Operating pressure range Is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of spring return 1/8 ported valves are 4″ L x 1.375″ W x .75″ D. For 1/4 ported valves: 5.375″ L x 2″ W x 1″ D. Above panel dimensions including handle for 1/8-ported valves – 2.5″. 1/4-ported valves -3.375″. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75023-91-00

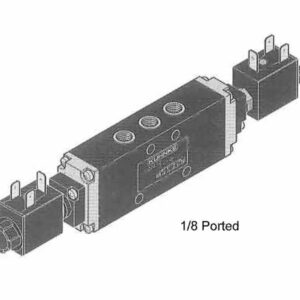

Solenoid operated, air piloted spool valves are available in single, double, priority and external air pilot versions. Valve designs use a stainless steel spool moving within a sleeve to direct airflow to the ports of the valve. Spool valves are known for their long life capability.

Valves are available in 1/8 and 1/4 port sizes and have an operating range of 35 to 145 PSI.

Valves include a red manual override and encapsulated coils and can be individually mounted or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures.)

Through body mounting holes are 3/16″.

For valve specifications see appendix. See accessory section for electrical connectors and manifolds. For detail dimensions contact factory.

Item # 75023-27-42

Knob valves have a small travel of about 1/4 inch and can be easily operated with the palm of a hand. Knobs are constructed of sturdy black molded material. Available in spring return, pneumatic return and push-pull versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI: 1/8 port approx. 3.4 Lbs., 1/4 port 11.3 Lbs.

For normally open function on 3 way valves reverse connect ports 1-3. For 2 way operation, plug port 3. Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Above panel dimensions: 1/8-ported are 1″ Dia. x 1.5? H: 1/4-ported -1.5″ Dia. x 2.25″ H.

Typical behind panel dimensions of 4 way 1/8 ported valves are 2.5″ D x 1.375″ W x 0.75″ H; 1/4 ported valves- 4″ D x 2″ W x 1″ H. For 3 way valves subtract 0.75″ from depth. For pneumatic return add 1″ to depth dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75044-02-00

Solenoid operated, air piloted poppet valves are available in single, double, priority and external air pilot supply versions. Priority version overrides signal from opposite solenoid to assure return to valve home position. Valves with external air pilot connections are used when switching pressures below 35 PSI. Poppet valves usually provide higher flow rates than other types of valves because of flow path design. Valves include a red manual override for easy testing. Encapsulated coils provide splash proof protection when used with plug connectors. Valves can be mounted individually using through body holes or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures).

Through body mounting holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4″ for 1/2 ported valves.

For valve specifications see appendix. See accessory section for electrical connectors. For detail dimensions contact factory.

Item # 75024-25-38

Three position valves are used mostly to position cylinders manually. The operator controls the cylinder direction by moving the lever side to side. Valves with all ports open in the center position allow the cylinder piston rod to move freely, while valves with all ports closed in the center position will hold the cylinder in the desired position when the lever is returned lo center. Valves can be panel or body mounted.

Operating pressure range Is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of spring return 1/8 ported valves are 4″ L x 1.375″ W x .75″ D. For 1/4 ported valves: 5.375″ L x 2″ W x 1″ D. Above panel dimensions including handle for 1/8-ported valves – 2.5″. 1/4-ported valves -3.375″. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75023-91-00

Solenoid operated, air piloted spool valves are available in single, double, priority and external air pilot versions. Valve designs use a stainless steel spool moving within a sleeve to direct airflow to the ports of the valve. Spool valves are known for their long life capability.

Valves are available in 1/8 and 1/4 port sizes and have an operating range of 35 to 145 PSI.

Valves include a red manual override and encapsulated coils and can be individually mounted or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures.)

Through body mounting holes are 3/16″.

For valve specifications see appendix. See accessory section for electrical connectors and manifolds. For detail dimensions contact factory.

Item # 75023-27-42

Knob valves have a small travel of about 1/4 inch and can be easily operated with the palm of a hand. Knobs are constructed of sturdy black molded material. Available in spring return, pneumatic return and push-pull versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI: 1/8 port approx. 3.4 Lbs., 1/4 port 11.3 Lbs.

For normally open function on 3 way valves reverse connect ports 1-3. For 2 way operation, plug port 3. Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Above panel dimensions: 1/8-ported are 1″ Dia. x 1.5? H: 1/4-ported -1.5″ Dia. x 2.25″ H.

Typical behind panel dimensions of 4 way 1/8 ported valves are 2.5″ D x 1.375″ W x 0.75″ H; 1/4 ported valves- 4″ D x 2″ W x 1″ H. For 3 way valves subtract 0.75″ from depth. For pneumatic return add 1″ to depth dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75044-02-00

Solenoid operated, air piloted poppet valves are available in single, double, priority and external air pilot supply versions. Priority version overrides signal from opposite solenoid to assure return to valve home position. Valves with external air pilot connections are used when switching pressures below 35 PSI. Poppet valves usually provide higher flow rates than other types of valves because of flow path design. Valves include a red manual override for easy testing. Encapsulated coils provide splash proof protection when used with plug connectors. Valves can be mounted individually using through body holes or assembled on manifolds.

Operating pressure range is 35 to 145 PSI. (Use valves with external pilot for switching lower pressures).

Through body mounting holes are 3/16″ for 1/8 and 1/4 ported valves, 1/4″ for 1/2 ported valves.

For valve specifications see appendix. See accessory section for electrical connectors. For detail dimensions contact factory.

There are no reviews yet.