| Description | Manifold Section ISO 1 |

Item # 76420-00-13

Price Summary

- $47.96

- $47.96

- $47.96

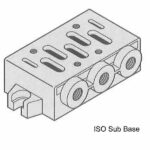

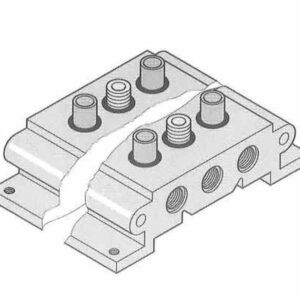

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

| Weight | 0.19 lbs |

|---|

Be the first to review “Item # 76420-00-13” Cancel reply

You must be logged in to post a review.

Related Products

Item # 76420-00-12

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Item # 76420-00-11

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Item # 76420-00-14

Manifold sections can be used to extend existing systems. Units include the necessary hardware for mounting. Sub bases can be used to individually mount ISO valves.

For a complete list of components including headers, interconnecting parts, blanking plates and hardware for new ISO valve installations, contact the factory.

Recently Viewed

Item # 76440-02-02

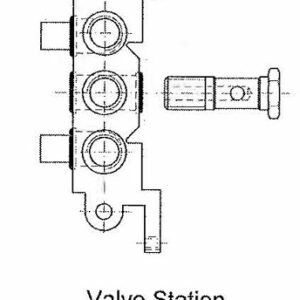

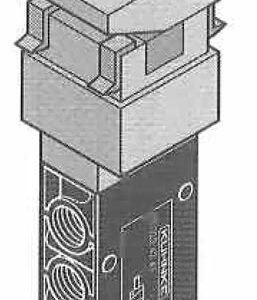

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 76420-02-03

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 75023-42-42

Shrouded Head helps prevent accidental operation of button.

Operating pressure range std. type- 0-145 PSI; air piloted types minimum 35 PSI. Actuation force: std. – 7.9 lbs., air pilot assisted types 1.8 Ibs.

Above panel dim. are 1.125″ dia. x .5″ H (shroud) or 1.25″ H (mushroom). Behind panel dim. are 4″ (3 way). 4.5″ (4 way) D. x 1.375″ H x .75 W.

For valve specifications see appendix. For detail dimensions contact factory.

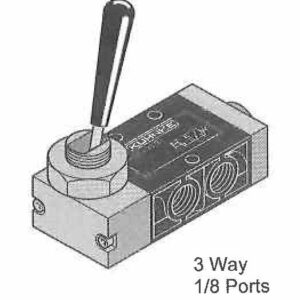

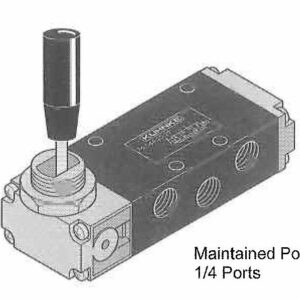

Item # 75042-25-00

Lever valves can be used to manually switch air supplies on equipment or operate cylinders and other devices. Valves can be panel mounted or fastened to a surface via body mounting holes. Handles have a contemporary black molded grip and require 3.4 lbs. of force to operate. Valves are available in spring return, pneumatic return and maintained position versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

For normally open function on 3 way valves, reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4 ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of 4 way 1/8 ported valves are 3.75″ L x 1.375″ W x 0.75″ D. For 1/4 ported valves: 4.75″ L x 2″ W x 1″ D. For 3 way valves subtract 0.75″ from L dimension. For pneumatic return valves add 1″ to L dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

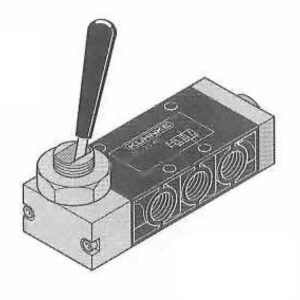

Item # 75043-25-40

Lever valves can be used to manually switch air supplies on equipment or operate cylinders and other devices. Valves can be panel mounted or fastened to a surface via body mounting holes. Handles have a contemporary black molded grip and require 3.4 lbs. of force to operate. Valves are available in spring return, pneumatic return and maintained position versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

For normally open function on 3 way valves, reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4 ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of 4 way 1/8 ported valves are 3.75″ L x 1.375″ W x 0.75″ D. For 1/4 ported valves: 4.75″ L x 2″ W x 1″ D. For 3 way valves subtract 0.75″ from L dimension. For pneumatic return valves add 1″ to L dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

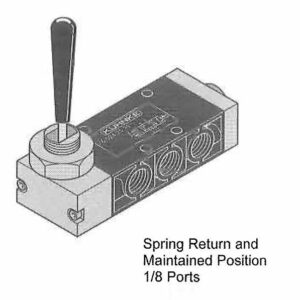

Item # 76044-25-38

Three position valves are used mostly to position cylinders manually. The operator controls the cylinder direction by moving the lever side to side. Valves with all ports open in the center position allow the cylinder piston rod to move freely, while valves with all ports closed in the center position will hold the cylinder in the desired position when the lever is returned lo center. Valves can be panel or body mounted.

Operating pressure range Is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of spring return 1/8 ported valves are 4″ L x 1.375″ W x .75″ D. For 1/4 ported valves: 5.375″ L x 2″ W x 1″ D. Above panel dimensions including handle for 1/8-ported valves – 2.5″. 1/4-ported valves -3.375″. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75023-23-42

Used as a pneumatic limit switch or position detector. Roller arm travel is 3/8? (10mm). Actuating force is 4.5 Lbs. Options include valves with pneumatic reset used in conjunction with other controlling devices to reset valve. A double roller lever valve can be used on machine carriages to reverse direction of travel.

Operating pressure range is 0-145 PSI. Actuation force @ 90 PSI, is approx. 4.5 Lbs.

For normally open function on 3 way valve, reverse connect ports 1-3. For 2 way operation, plug port 3.

Typical valve body dimensions are 2.5? L (3 way), 3.15? L (4 way) x 1.375? H x .75? W. Add 1? to L dim. for pneumatic reset types. Through body mounting holes are 3/16? diameter.

Roller Lever extends 1.343? beyond body and travel is .39? +/- .04?.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 76440-02-02

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 76420-02-03

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

Item # 75023-42-42

Shrouded Head helps prevent accidental operation of button.

Operating pressure range std. type- 0-145 PSI; air piloted types minimum 35 PSI. Actuation force: std. – 7.9 lbs., air pilot assisted types 1.8 Ibs.

Above panel dim. are 1.125″ dia. x .5″ H (shroud) or 1.25″ H (mushroom). Behind panel dim. are 4″ (3 way). 4.5″ (4 way) D. x 1.375″ H x .75 W.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75042-25-00

Lever valves can be used to manually switch air supplies on equipment or operate cylinders and other devices. Valves can be panel mounted or fastened to a surface via body mounting holes. Handles have a contemporary black molded grip and require 3.4 lbs. of force to operate. Valves are available in spring return, pneumatic return and maintained position versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

For normally open function on 3 way valves, reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4 ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of 4 way 1/8 ported valves are 3.75″ L x 1.375″ W x 0.75″ D. For 1/4 ported valves: 4.75″ L x 2″ W x 1″ D. For 3 way valves subtract 0.75″ from L dimension. For pneumatic return valves add 1″ to L dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75043-25-40

Lever valves can be used to manually switch air supplies on equipment or operate cylinders and other devices. Valves can be panel mounted or fastened to a surface via body mounting holes. Handles have a contemporary black molded grip and require 3.4 lbs. of force to operate. Valves are available in spring return, pneumatic return and maintained position versions.

Operating pressure range is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

For normally open function on 3 way valves, reverse connect ports 1-3. For 2 way operation, plug port 3.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4 ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of 4 way 1/8 ported valves are 3.75″ L x 1.375″ W x 0.75″ D. For 1/4 ported valves: 4.75″ L x 2″ W x 1″ D. For 3 way valves subtract 0.75″ from L dimension. For pneumatic return valves add 1″ to L dimension. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 76044-25-38

Three position valves are used mostly to position cylinders manually. The operator controls the cylinder direction by moving the lever side to side. Valves with all ports open in the center position allow the cylinder piston rod to move freely, while valves with all ports closed in the center position will hold the cylinder in the desired position when the lever is returned lo center. Valves can be panel or body mounted.

Operating pressure range Is 0-145 PSI. Actuation force at 90 PSI, is approx. 3.4 Lbs.

Panel mounting hole size for 1/8-ported valves is 5/8 inch diameter, for 1/4-ported valves, 7/8 inch. Through body mounting holes are 3/16″ dia.

Typical dimensions of spring return 1/8 ported valves are 4″ L x 1.375″ W x .75″ D. For 1/4 ported valves: 5.375″ L x 2″ W x 1″ D. Above panel dimensions including handle for 1/8-ported valves – 2.5″. 1/4-ported valves -3.375″. Allow space for fittings and tubing.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 75023-23-42

Used as a pneumatic limit switch or position detector. Roller arm travel is 3/8? (10mm). Actuating force is 4.5 Lbs. Options include valves with pneumatic reset used in conjunction with other controlling devices to reset valve. A double roller lever valve can be used on machine carriages to reverse direction of travel.

Operating pressure range is 0-145 PSI. Actuation force @ 90 PSI, is approx. 4.5 Lbs.

For normally open function on 3 way valve, reverse connect ports 1-3. For 2 way operation, plug port 3.

Typical valve body dimensions are 2.5? L (3 way), 3.15? L (4 way) x 1.375? H x .75? W. Add 1? to L dim. for pneumatic reset types. Through body mounting holes are 3/16? diameter.

Roller Lever extends 1.343? beyond body and travel is .39? +/- .04?.

For valve specifications see appendix. For detail dimensions contact factory.

Item # 76440-02-02

Two sizes of manifold kits are available (1/8 and 1/4 ported) for standard directional control valves, pneumatically or electrically operated (4 way, In-Line type, 2 or 3 position, except valve types 76123, 76124, 76127). Manifolds are single piece aluminum bases with common supply and exhaust ports on each end (1/8 or 1/4 metric respectively). For NPT supply ports, order supply line adaptor kit separately. Manifold kits include all valve mounting hardware, which accommodates both NPT, or Metric ported versions of valves. A hollow bolt is used to connect the valve to the base and supply the line air pressure. Two brass sleeves, sealed with O-rings, connect the exhaust ports. If a valve station is unoccupied (for future use), a blanking bar kit must be used to block manifold ports. Manifolds can be fastened down by 4 threaded M5 holes. Two or more 1/8 ported manifolds can be linked together with the use of connecting nipples and threaded tie rods (up to 3/16″ dia.) using the through body holes on the sides of the manifold to increase the number of stations.

There are no reviews yet.